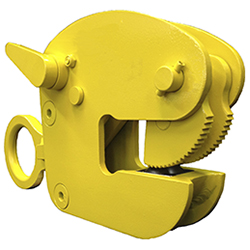

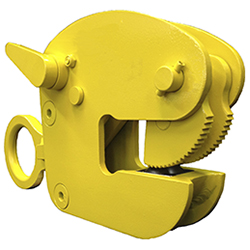

Model VL

The Model VL is the core of our vertical locking clamps. With it’s long list of standard features your one Safety Clamp can do the job of many different model clamps offered by others. One clamp does it all. And when you purchase the Model VL clamp, you may choose any additional option or combination of options needed for your specific lifting application. For example, you have chosen the Model VL but realize your lift requires the clamp to be side loaded. Simply add the Universal Shackle option to the Model VL and you are ready to make a side load lift up to 90 degrees. And if you are lifting stainless material and are concerned with the grippers contaminating the stainless, order your Model VL with the optional serrated stainless grippers for a more secure lift with no contamination.

The standard lock handle on your Safety Clamp not only allows you to rotate the material you are lifting but also allows the operator to remotely release the clamp from the material when it is at rest and secured. Simply attach a tag line to the pre-drilled hole in the handle and pull it to release the clamp from the material and lock the clamp open for easy removal.

The Model VL incorporates the functions of numerous models of clamps made by others into one easy to use product.

Model VL – Vertical Lifting Clamp Features

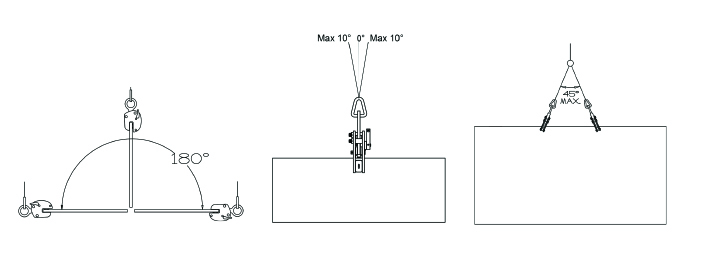

Lifts from Horizontal to Vertical through a 180° arc

- Capable of lifting material from a horizontal to vertical position before vertically transferring the material to another location. It is also designed to rotate material from a horizontal position to vertical and then roll the material over onto it’s other side through a 180° arc.

Locks Open and Locks Closed

- Locks open to protect the grippers when loading and unloading clamp.

- Locks closed onto material for a more secure lift.

Remote Release Lock Handle

- By attaching a tag line to the lock handle, the operator is able to lock open the clamp from a distance when the load is at rest and secured.

- Also available: Double Remote Locking Handle that also allows the operator to lock the clamp closed when loading the clamp from a distance using a second tag line.

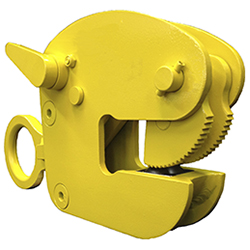

3 Point Grip System

- Unique design has dual upper grippers that rotate into the jaw and a self aligning lower gripper pad to give you 3 separate gripping points for more stability and longer gripper life. Available on rated capacities of 2 ton and up.

Rated to lift material with a surface hardness up to 450 Brinell

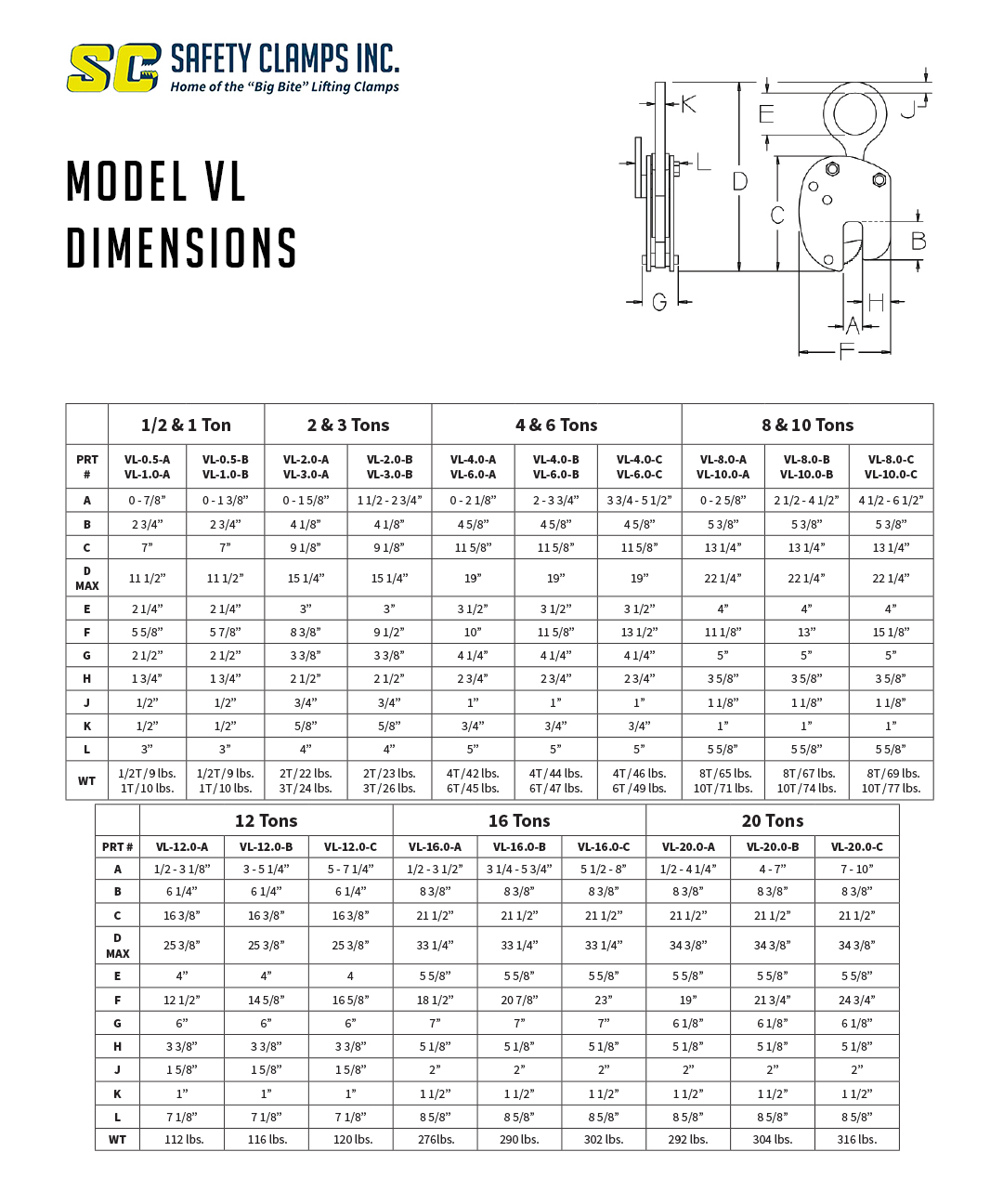

Wide Jaw Openings – 2 to 3 times larger than other brands

- Safety Clamps, Inc. offers the widest standard jaw openings in the industry. Lower up front clamp cost, more diverse lifts, and less operator change out time.

High Strength Shock Resistant Steel

- Provides for longer clamp life.

Working Parts Protected

- Working parts remain inside the body at all times whether in the “locked closed” position or the “locked open” position. This protects the working parts from damage when rolling material over and when the clamp is stored and provides for longer clamp life.

Special Jaw Openings Available

- Fit the jaw opening to your material thickness range.

- Extend the grippers out for clearance.

- Shape the jaw opening to accommodate your lift.